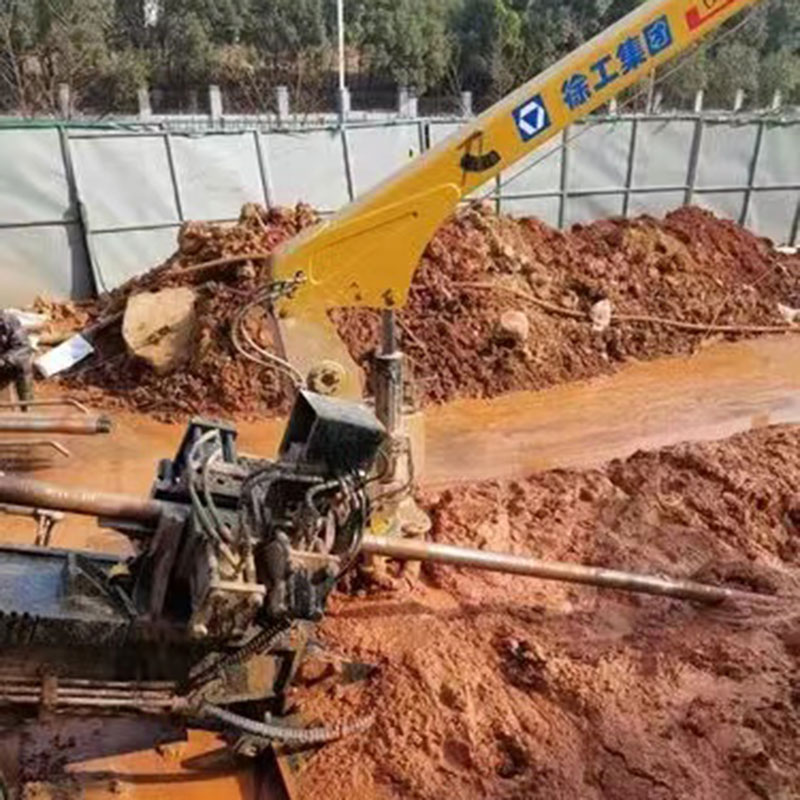

Thickening of bentonite by trenchless drilling of sodium-based calcium based piling

the specific role of mud bentonite

(1) Protection of the hole wall: mud bentonite can produce a large number of high-viscosity mud, which can penetrate, bond, and reinforce in the sand and stone gaps of the inner wall of the hole, thereby playing a role in protecting the hole wall.

(2) Cooling lubrication drilling tool: when drilling to more sand or rock geological layer drilling, drilling tool and ground rock cutting is prone to excessive drilling resistance, and it is very easy to produce temperature aggravation and increase phenomenon, at this time we inject the mud made of bentonite into the well to cool and lubricate the drilling tool, reduce the drilling pressure, and effectively prevent the burning of the drilling tool and improve the drilling rate.

(3) Balanced ground pressure: Due to the continuous increase of drilling depth, the pressure of the bottom of the well and the ground is easy to lose balance, and mud bentonite can form a thin mud cake around the hole wall of the well, thereby balancing the ground pressure in the well.

(4) Upward return cuttings: high-viscosity bentonite mud can flow out along the hollow of the drill pipe and into the middle hole at the top of the drilling tool, which can adhere to the cuttings and sand at the bottom of the well and rotate along the continuous rotation of the drill pipe to carry it out of the well, so as to keep the bottom of the well clean.

(5) Improve the security of the pile wall: In the area of high depth and rock layer, drilling mud bentonite can ensure the reliability of the pile wall.

Needless to say, as long as the construction personnel engaged in drilling projects can feel that bentonite is the key material for drilling retaining wall holes, and its quality can directly affect the success or failure of drilling projects.